Planned Maintenance Software

Smart, Integrated, and Compliant PMS Software for Ships

Ensure the safety and efficiency of your fleet with NOZZLE’s cloud-based Planned Maintenance System (PMS). As one of the most vital components of vessel management, PMS helps shipowners and managers minimize downtime, optimize costs, and enhance compliance with international regulations like ISM, TMSA, and SIRE 2.0.

With NOZZLE PMS, you can schedule, assign, track, and analyze every maintenance task, critical equipment, or spare part—ensuring uninterrupted operations and compliance with OCIMF and IMO standards.

NOZZLE automates maintenance planning, reducing the risk of unexpected breakdowns while improving fleet-wide performance. Whether it’s routine servicing or emergency repairs, our solution helps you stay ahead.

Reasons to choose NOZZLE PMS

Why Choose NOZZLE PMS?

- Cloud-Based Efficiency – Access maintenance data anytime, anywhere.

- Automated Scheduling – Set up recurring maintenance tasks effortlessly.

- Seamless Procurement Integration – Link spare parts directly to maintenance tasks.

- Regulatory Compliance – Ensure ISM, TMSA, and SIRE 2.0 compliance.

- Enhanced Fleet Safety – Reduce the risk of failures with predictive maintenance.

- ClassNK & DNV Type Approved – Meets the highest classification society standards.

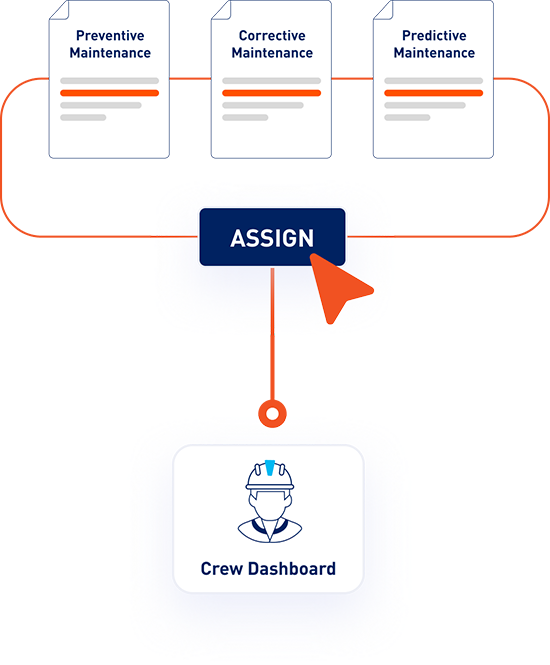

Work Orders

Automate and Track Ship Maintenance Tasks Features:

Ship maintenance requires efficient scheduling and execution to prevent costly downtime. NOZZLE’s Work Order system ensures all planned and unplanned maintenance tasks are properly tracked and executed. With automated scheduling and real-time updates, shipowners can prioritize critical repairs and reduce delays.

- Scheduled & Unplanned Work Orders – Automatically generate work orders for planned maintenance while allowing manual creation for emergency repairs.

- Approval & Postponement Workflow – Work orders can be approved, postponed, or rescheduled based on fleet priorities.

- Critical Task Identification – Classify tasks by priority, ensuring urgent ship maintenance tasks get immediate attention.

- ISM & Risk Assessment Compliance – Automatically attach ISM Forms and risk assessments to maintenance tasks.

Job Pool

Centralized Planning for Maintenance Tasks

Managing multiple vessels requires a structured maintenance approach to ensure compliance and efficiency. The Job Pool acts as a centralized task repository, allowing fleet managers to standardize maintenance workflows. With predefined job plans, shipowners can avoid inconsistencies and reduce administrative workload. Features:

- Predefined Task Repository – Store recurring maintenance jobs and assign them automatically to ships.

- Customizable Job Plans – Define triggers, required resources, and expected completion times for each maintenance task.

- Integration with Work Orders – Seamlessly convert job pool entries into scheduled maintenance tasks.

- Compliance with Regulations – Assign ISM reports, risk assessments, and spare parts logs to job plans.

Equipment Management

Monitor Ship Equipment Performance & Lifecycle

Ships rely on complex machinery that requires continuous monitoring to avoid failures. NOZZLE’s Equipment Management module allows shipowners to track equipment history, monitor performance, and schedule maintenance before failures occur. By integrating equipment data, fleet managers gain full visibility into asset conditions. Features:

- Comprehensive Equipment Registry – Store detailed records for all ship machinery, engines, and critical systems.

- Lifecycle & Condition Monitoring – Track usage data, warranty details, and maintenance history in one place.

- Nested Equipment Structure – Define systems, units, and components in a structured hierarchy for easy management.

- Performance Analysis with Measurement Logs – Log running hours, pressure levels, and power consumption for predictive maintenance.

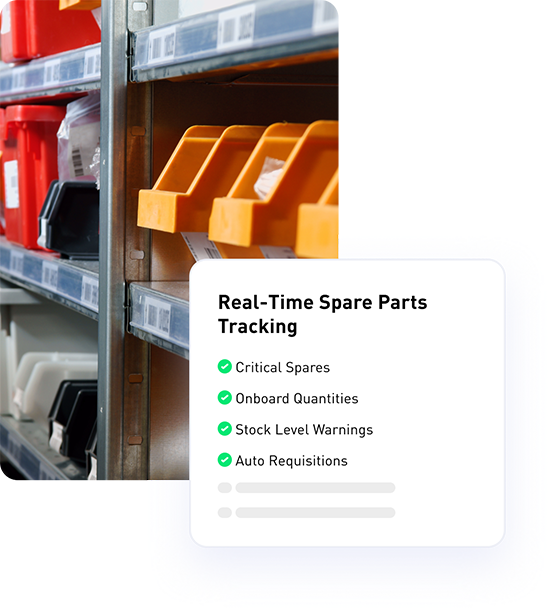

Spare Parts & Procurement

Automated Spare Part Tracking & Requisitioning

A well-managed spare parts inventory is essential to prevent vessel downtime. NOZZLE’s Spare Parts module connects inventory, procurement, and maintenance systems, ensuring critical spare parts are available when needed. The system automatically alerts users when stock is low, preventing last-minute shortages.

Features:

- Real-Time Stock Monitoring – Track onboard spare part quantities and receive alerts for low stock.

- Automated Requisitions – Generate purchase requests when critical spare parts reach minimum levels.

- Seamless Procurement Integration – Connect PMS with inventory and supplier management for quick replenishment.

- Supplier Claims & Warranty Tracking – Log defective parts, warranty claims, and procurement disputes efficiently.

Running Hours & Measurements

Monitor Equipment Usage for Predictive Maintenance

Equipment maintenance should be based on actual operating conditions, not just fixed schedules. NOZZLE’s Running Hours & Measurement Logs track operating hours, wear indicators, and performance data to trigger maintenance only when necessary. This prevents over-maintenance and reduces costs.

Features:

- Track Equipment Running Hours – Record engine operating times, fuel consumption, and wear & tear indicators.

- Set Custom Measurement Points – Define key monitoring points like RPM, pressure, and temperature levels.

- Automatic Counter Updates – Update all sub-equipment readings when main equipment usage is logged.

- Maintenance Triggers for Critical Components – Schedule maintenance based on performance thresholds.

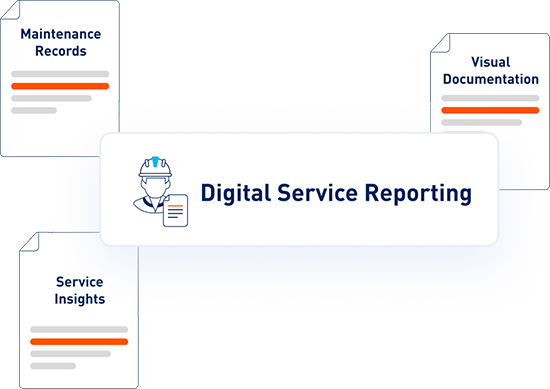

Service & Engineer Reports

Maintain Accurate Records of Maintenance & Repairs

Accurate service records help shipowners track repairs, inspections, and compliance issues. NOZZLE’s Service & Engineer Reports module allows detailed documentation of maintenance activities, including photos, technical descriptions, and corrective actions. This ensures regulatory compliance and better decision-making.

Features:

- Digital Maintenance Logs – Engineers can record detailed service reports, including images and documents.

- Automated Report Generation – Attach engineer findings, compliance checklists, and corrective actions to each maintenance task.

- Historical Data Access – Retrieve past service reports for audits, regulatory inspections, and performance reviews.

- ANTBI Compliance Tracking – Link reports with non-conformity (ANTBI) issues for corrective action tracking.

Drydock Management

Efficiently Plan & Track Drydock Activities

Drydock periods are critical for major vessel maintenance and inspections. NOZZLE’s Drydock Management module helps shipowners coordinate maintenance schedules, ensuring all necessary repairs and upgrades are completed efficiently. With built-in work order integration, fleet managers can track costs, supplier performance, and certification renewals.

Features:

- Scheduled Drydock Planning – Maintain a detailed timeline of drydock periods for vessel inspections and repairs.

- Work Order & ANTBI Linking – Connect drydock tasks with work orders and non-conformity (ANTBI) reports.

- Supplier & Budget Tracking – Manage shipyard selection, cost estimations, and approvals in one platform.

- Certification Renewal Alerts – Keep track of expiring certificates and plan drydock sessions accordingly.

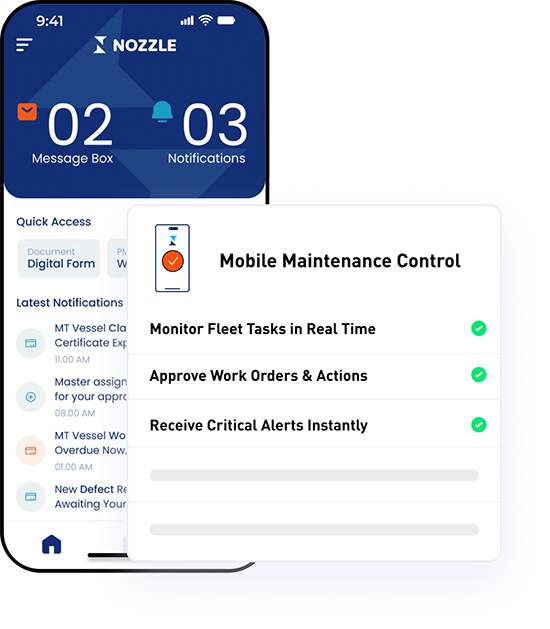

PMS Mobile App

Manage Ship Maintenance Anytime, Anywhere

Technical Managers and Superintendents are constantly traveling between vessels, making real-time access to maintenance workflows essential. NOZZLE’s PMS Mobile App allows them to monitor work orders, approve tasks, and manage postponements—all from their mobile device. This ensures continuous oversight and decision-making on the go, reducing delays and improving fleet efficiency.

Features:

- Real-Time Workflow Monitoring – Access live updates on ongoing, pending, and completed maintenance tasks from anywhere.

- On-the-Go Approvals – Instantly approve, reject, or postpone work orders without waiting to be at the office.

- Push Notifications & Alerts – Get instant alerts for critical maintenance tasks, overdue work orders, and approval requests.

- User-Friendly Interface – Designed for fast navigation, enabling ship managers to take action quickly, even with limited connectivity.

Compliance with ISM, TMSA, and OCIMF

NOZZLE PMS is designed to help ship operators meet:

- ISM Code – Ensuring safety and pollution prevention.

- TMSA Element 4 – Efficient onboard maintenance management.

- SIRE 2.0 Requirements – Compliance with OCIMF’s vessel inspections.

Upgrade Your Ship Maintenance with NOZZLE PMS

Take full control of your fleet’s maintenance with NOZZLE’s digital PMS solution. Improve reliability, reduce costs, and stay compliant with industry regulations—all from a single, cloud-based platform.

Request a Free Demo Today!

Testimonials

NOZZLE delivers reliable ship management solutions trusted by maritime companies worldwide. Our software helps fleets stay compliant, improve efficiency, and manage operations with confidence.